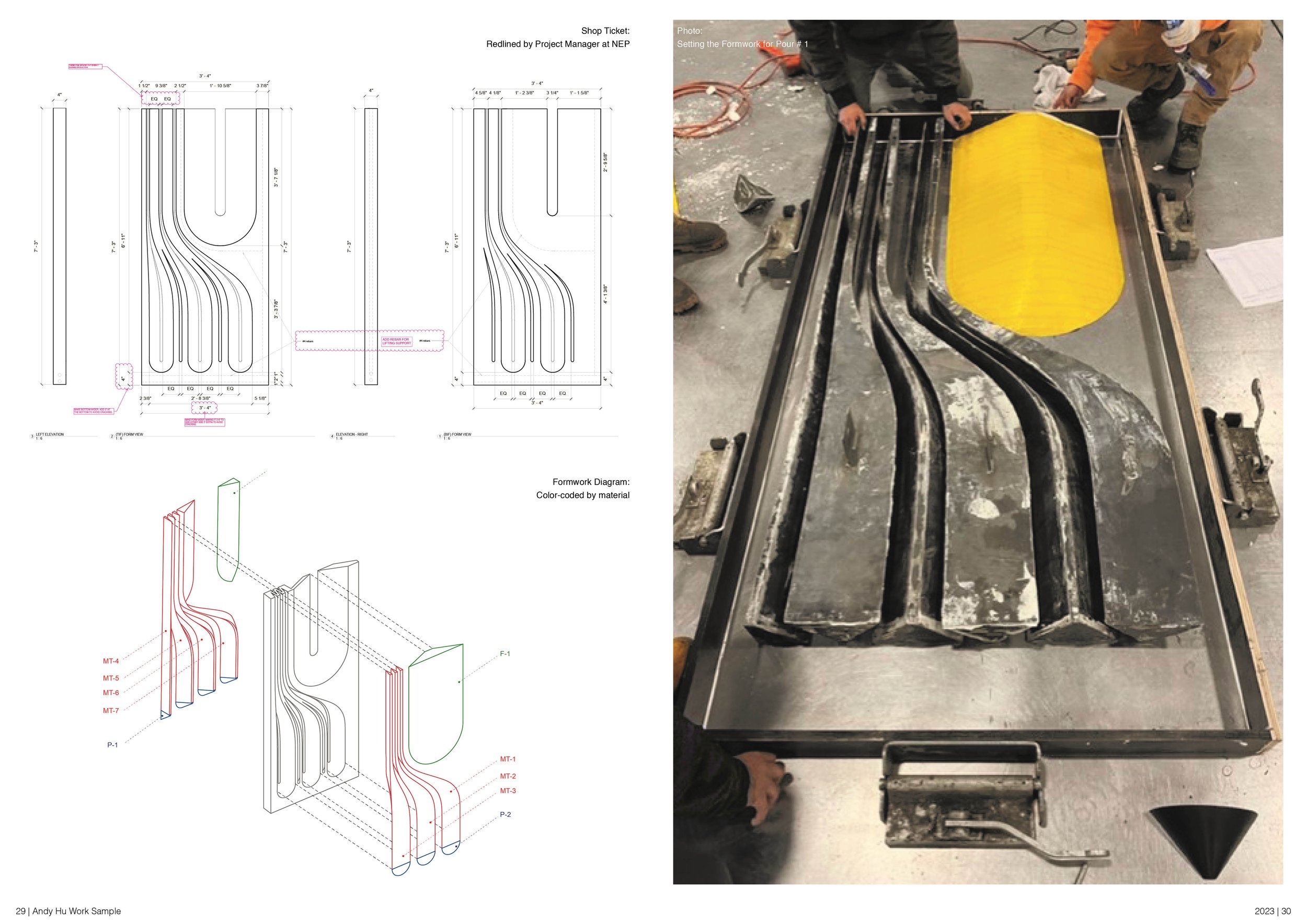

Group Built Project, 2022, UPenn Weitzman Arch. In collaboration with NorthEast Precast

UHPC does not require re-bar and can achieve a thinness unimaginable for traditional concrete mixes. Its thinness comes close to thick steel, but its aesthetic strength lie in doubly-curved surfaces and shapes of varying thickness. These strengths come from its property as a material that is cast into a mold.

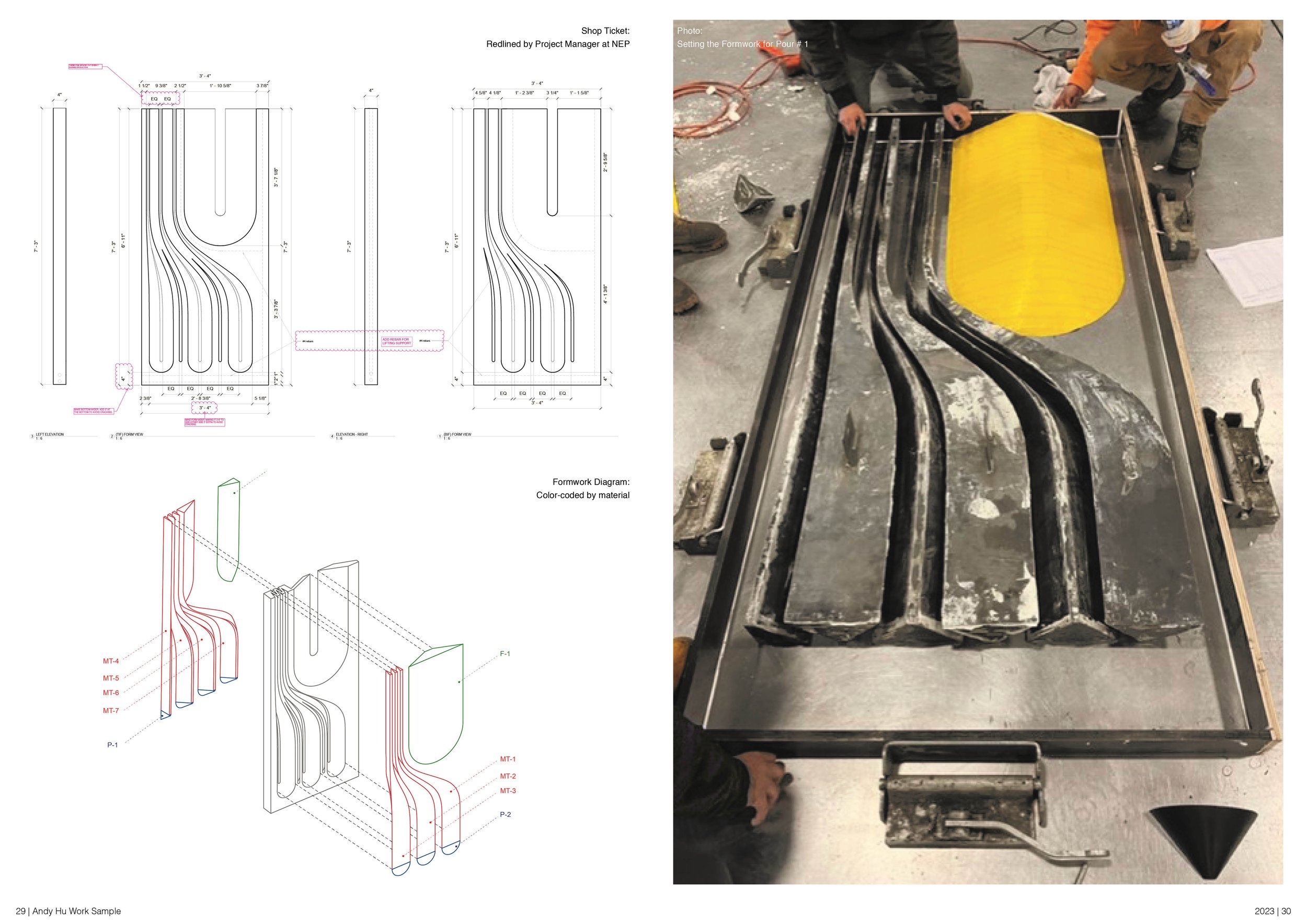

Our team of 4 at UPenn designed, developed and cast 3’x6’ UHPC panels with the team at NorthEast Precast. The majority of formwork was made from welded sheet-metal, which allowed the formwork to be reused.

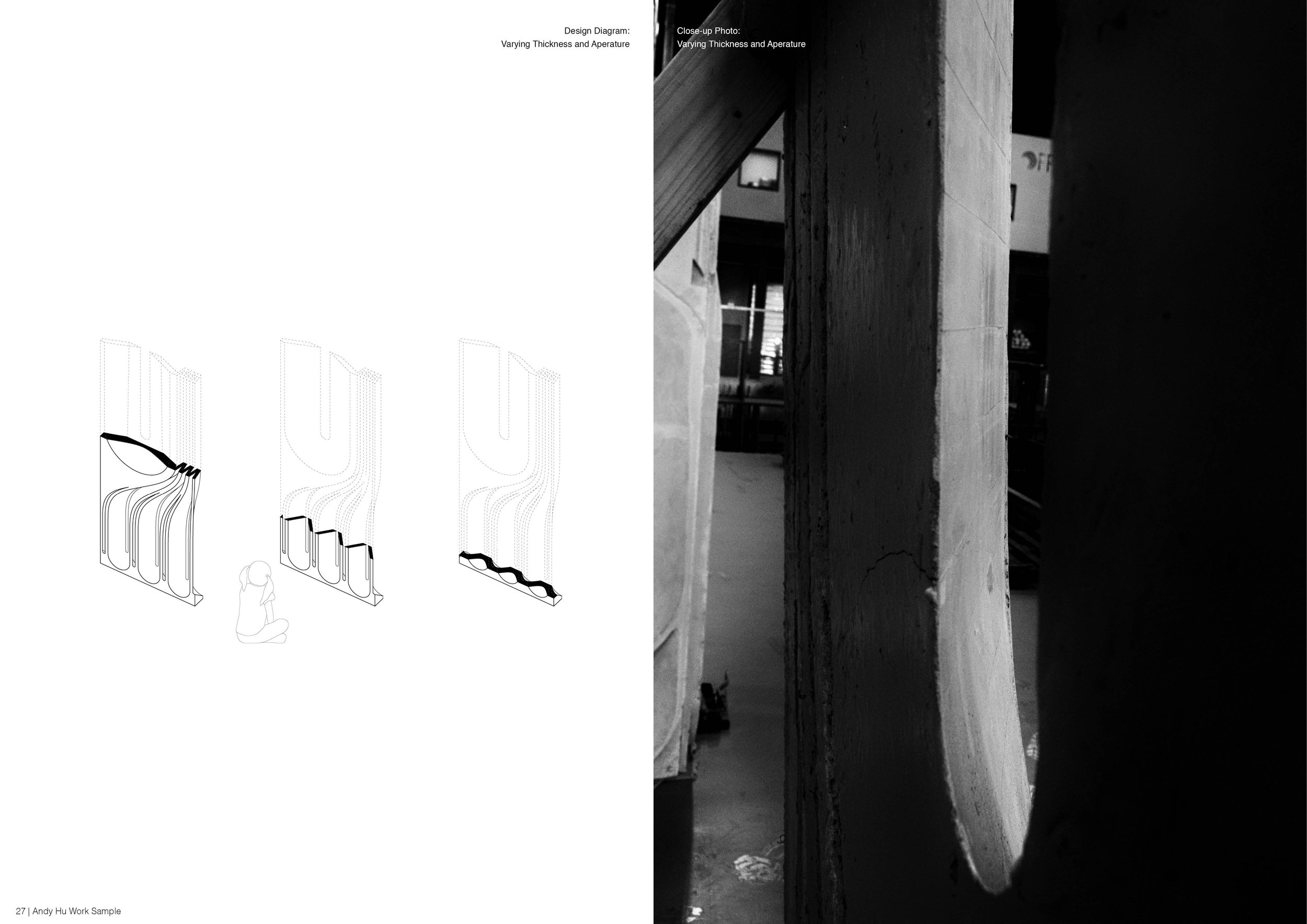

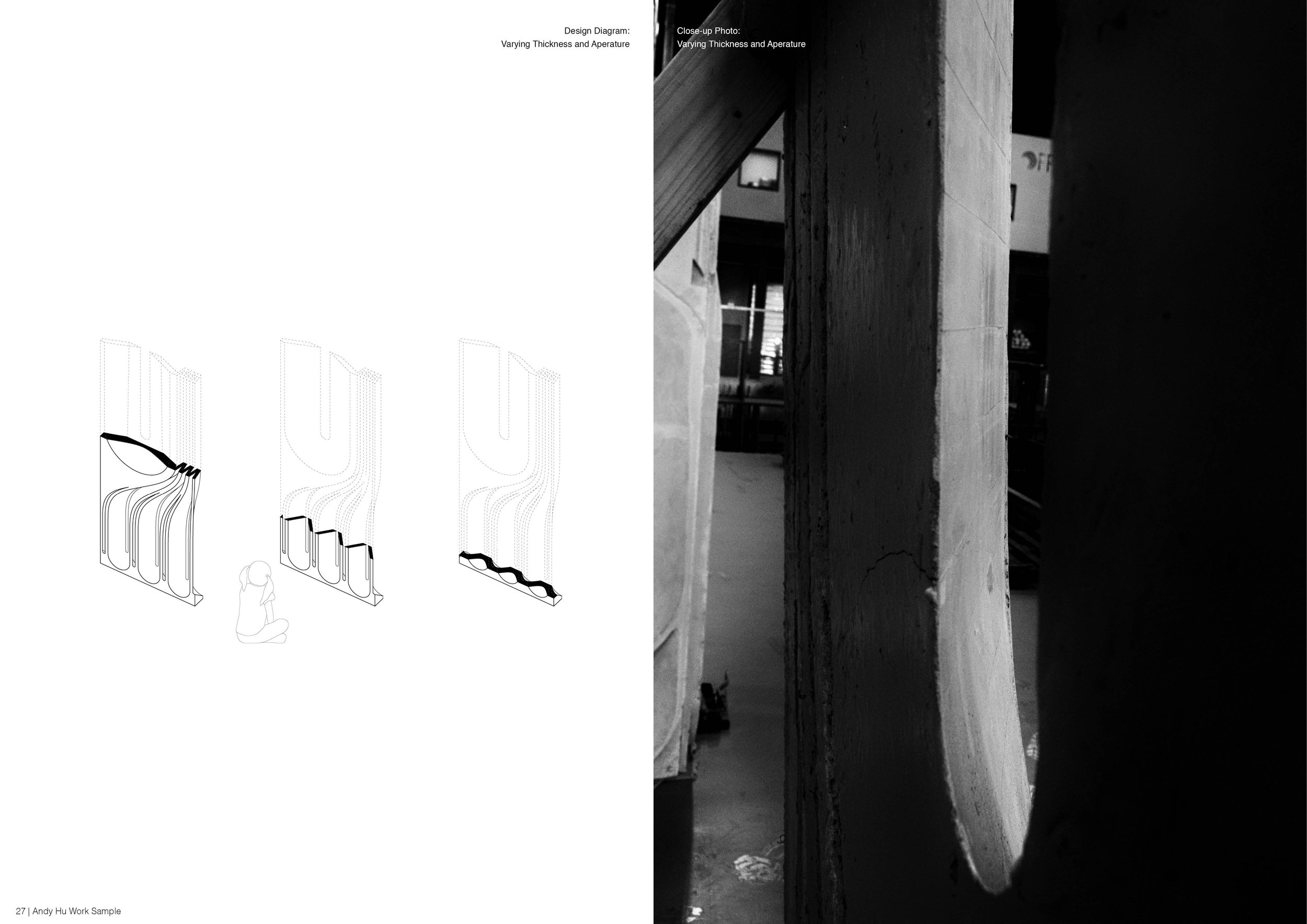

The design featured varying thicknesses and apertures, which advantage of the material strengths of UHPC.

Our group of 4 worked with NEP, under the guidance of Prof. Richard Garber to continually modify the design of the panel over 2 months in order to best realize our design intent.

Group Built Project, 2022, UPenn Weitzman Arch. In collaboration with NorthEast Precast

UHPC does not require re-bar and can achieve a thinness unimaginable for traditional concrete mixes. Its thinness comes close to thick steel, but its aesthetic strength lie in doubly-curved surfaces and shapes of varying thickness. These strengths come from its property as a material that is cast into a mold.

Our team of 4 at UPenn designed, developed and cast 3’x6’ UHPC panels with the team at NorthEast Precast. The majority of formwork was made from welded sheet-metal, which allowed the formwork to be reused.

The design featured varying thicknesses and apertures, which advantage of the material strengths of UHPC.

Our group of 4 worked with NEP, under the guidance of Prof. Richard Garber to continually modify the design of the panel over 2 months in order to best realize our design intent.